Unilever High-Bay Warehouse

Location

Nyírbátor

Year of delivery

2023

Floor area

10.600 m²

Category

Logistics facilities

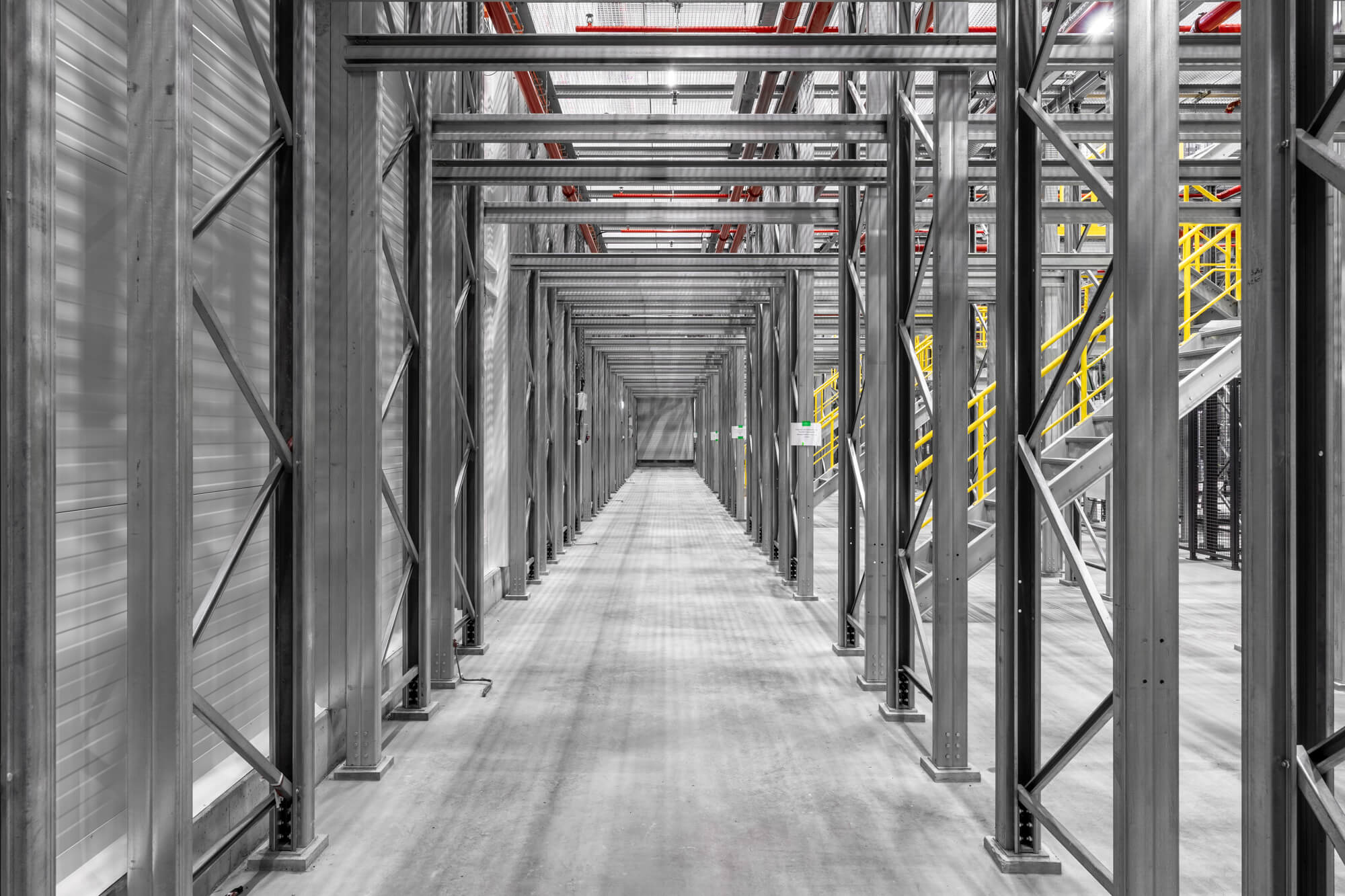

During the construction works, as the second phase of the Unilever household chemicals plant, a state-of-the-art, fully automated finished goods high-bay warehouse of 8,000 square metres and 32 metres in internal height was built, along with a 2,600-square-metre loading building. This investment complemented the first phase, completed one and a half years earlier, which included the construction of an 11,400-square-metre packaging hall and the commissioning of two new production lines. As a result of the development, Unilever’s manufacturing and storage capacities in Nyírbátor have increased, and new jobs have been created.

The construction works were carried out by Market Építő Zrt., with Lean Tech Mérnökiroda Kft. responsible for the general and architectural design, and TRAG-Plan & Engineering Services Kft. for the electrical engineering design – thus keeping the entire project under the control of the Market Group. As a result of the development, the plant’s annual production capacity increased from the previous 300 million tonnes to 500 million tonnes, and part of the bottles are now manufactured using recycled plastic.

In connecting the high-bay warehouse and the loading building, the linking corridor (bridge) had a total floor area of 187 m², with a layout resembling the letter “C”, which meant two directional breaks during construction. The level difference of the industrial floor base was set at 0 cm, while the foundation of the high-bay warehouse required 326 bored piles. The works were made more difficult not only by the need to maintain traffic flow on the road beneath the bridge throughout the entire construction period, but also by the requirement to coordinate daily with the factory and to prepare a daily organisation plan.

The superstructure of the loading building consists of prefabricated reinforced concrete, and three stairwells as well as a goods lift were also built. The base slab was poured in eight stages due to the lack of a large concrete plant in the vicinity.