MCS Slaughterhouse

Location

Mohács

Construction period

2015-2017

Floor area

26.000 m²

Category

Industrial facilities

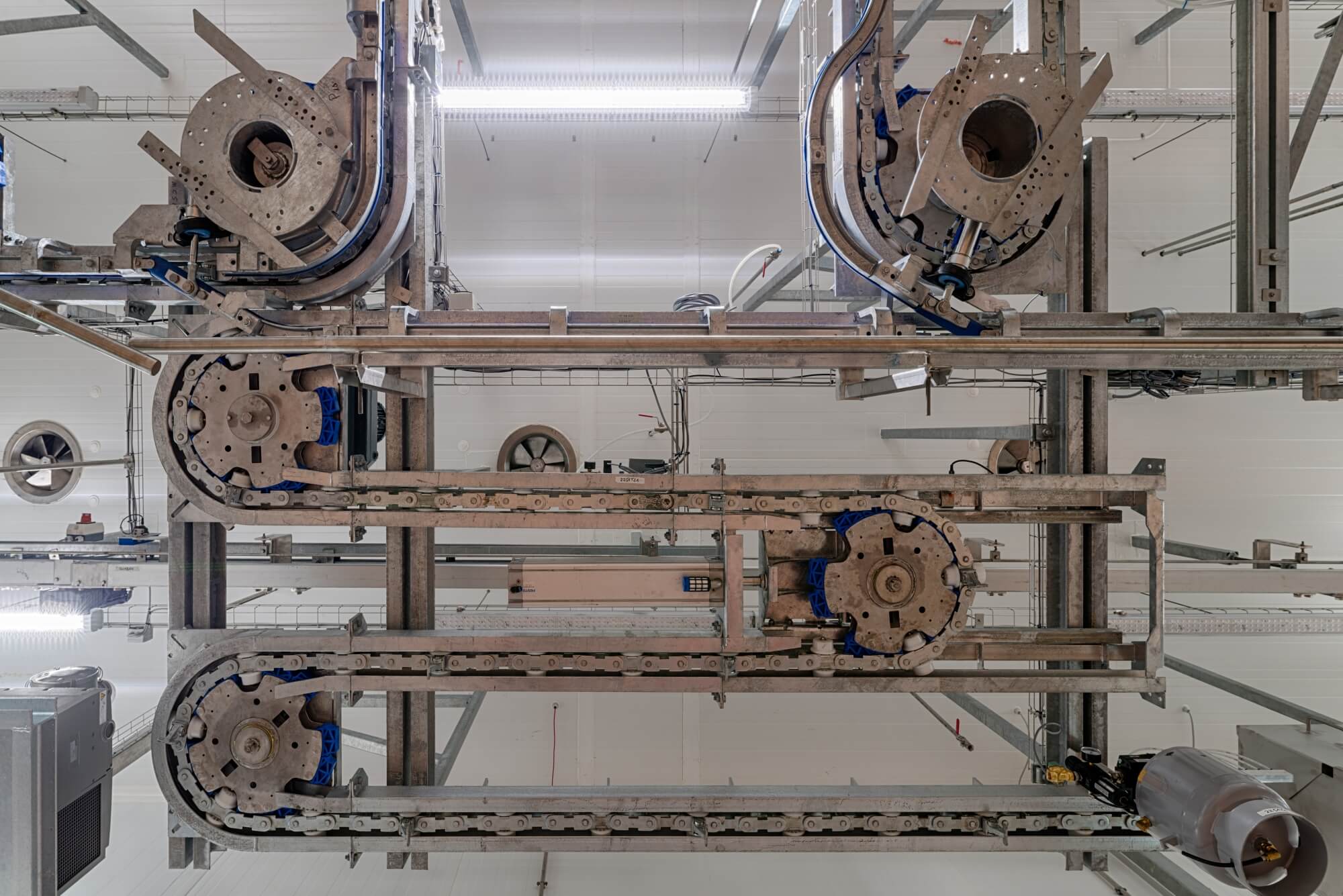

In 2017, the new plant of MCS Vágóhíd Zrt. opened its gates in Mohács – an enterprise that has since matured into one of Hungary’s most modern, sustainably operated and cost-efficient meat-processing facilities. As Market Építő Zrt.’s first slaughterhouse project, this investment was a significant milestone in the company’s history: the project posed a considerable challenge not only due to the complexity of construction, but also because the design and execution of the new functions had to proceed in parallel. Despite its complexity, the building was completed in just 20 months as part of a greenfield investment. Over the course of the works, 95,700 m³ of topsoil was removed, 78,000 m³ of soil improvement carried out, and 3,000 tonnes of steel structure installed.

The plant, with a floor area of nearly 26,000 m², is capable of slaughtering and complete processing 800,000 standard and 100,000 heavy pigs per year in a single shift. The technological design of the new facility enables it to meet the most stringent animal welfare, food safety and environmental requirements, and it is also certified to produce GMO-free meat, the first of its kind in Hungary.

The slaughterhouse also functions as a deboning, cutting and packaging plant, fully serving the integrated production chain of the Bonafarm Group. A large proportion of the processed livestock is sourced from the company’s own pig-farming division and from closely associated family-run and small enterprises. The meat produced here also supplies the factories of Pick Szeged Zrt., including the heavy sows essential for the famous Pick winter salami. In addition, the Mohács facility processes the raw materials used for mangalica products.

The investment was shaped not only by the ambition to expand processing capacity, but by a commitment to reduce the environmental footprint of production. Thanks to the innovative systems used, the plant’s operations consume 70% less water and 40% less energy compared to the previous unit in Szeged. This contributes significantly to the objectives of a sustainable food industry.

The Mohács plant thus stands as a cornerstone not merely for the Bonafarm Group but for the entire region: a stable market for local farmers, and a source of dependable, modern processing capability for the national food industry.